Installation Instructions

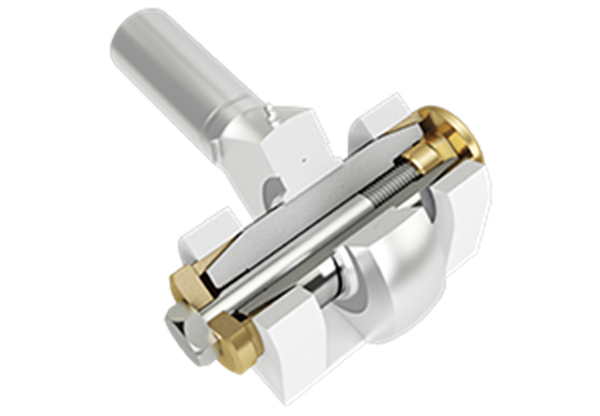

Straight Pin, Through Bolt

5.1

Following these instructions will ensure that the Expander System is installed correctly and the pivot life is prolonged.

Congratulations! You have purchased a custom engineered solution to the pivot wear problem on your machine. Contact your dealer or Expander before proceeding if you have any questions.

Expander System pivot pin comes with a warranty against lug wear of 10 years / 10 000 hours in operation (whichever comes first) from the date of purchase.

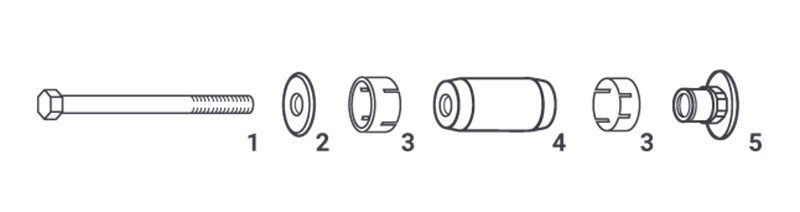

1 Bolt. 2 Washer. 3 Sleeve. 4 Axle (Pin). 5 Expander flat-headed nut for internal hexagon.

Preparation

Remove any bushings in the lugears to eliminate future wear between the bushing and the mounting lug.

Repair any structural damage i.e. cracks or bent lug ears before installation.

Smooth out any irregularities in the bore surfaces.

The difference between min and max diameter in the worn lugs must be within .06” (1.5 mm) for the sleeves to fit correctly.

ATTENTION! If the worn lugs diameter at any point is 2 mm (.080”) or more over original lug diameter contact your dealer or Expander System. You will need oversized sleeves.

Installation

Grease the sleeves and axle with grease available, preferably graphite grease. Do not grease the threads!

NOTE! If applicable: position greasing outlet 90 degrees to force direction to minimize stress concentration at outlet.

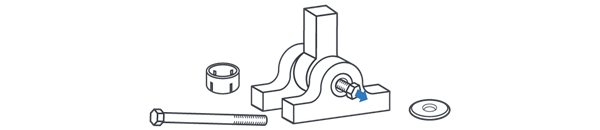

Install the Expander System loosely assembled. Position it in the bores and tighten the fastener. Hold the washer with a plier to prevent the axle from turning. Torque as specified.

Torque recommendations

Hex Bolts

Torques M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 70 | 115 | 175 | 350 | 500 | 600 | 700 | 900 |

| lb-ft | 52 | 85 | 129 | 258 | 369 | 443 | 516 | 664 |

Hex Nuts: Standard Height

Torques M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 65 | 115 | 175 | 250 | 350 | 500 | 600 | 700 |

| lb-ft | 48 | 85 | 129 | 184 | 258 | 369 | 443 | 516 |

Hex Nuts: Low Height

All Torques ± 10%

| M12 | - | M16 | M20 | M24 | M30 | - | - | |

| Nm | 60 | - | 125 | 200 | 275 | 350 | - | - |

| lb-ft | 44 | - | 92 | 148 | 203 | 258 | - | - |

Spanner Nuts

All Torques ± 10%

| M17 | M25 | M35 | M45 | M55 | M65 | M75 | M85 | |

| Nm | 50 | 120 | 250 | 500 | 600 | 700 | 800 | 900 |

| lb-ft | 37 | 89 | 184 | 369 | 443 | 516 | 590 | 664 |

Final Check

After initial torque, grease the pivot (if applicable), move the machine through full range of motion several times and recheck the torque. Check the torque after 10 hours, 40 hours and at regular service intervals to ensure proper seating of the sleeves.

Ensure that there is a minimum distance of 0,5 mm (0.02”) between the washer and the lug. NOTE! If flange design for easy removal of the sleeve is used there should be a minimum distance of 6 mm. ATTENTION! If the washer is in contact with the lug, contact your dealer or Expander System.

Dismounting

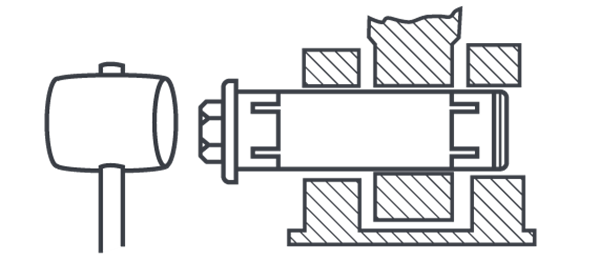

Dismount bolt and washer. Tap the axle until the tension on the sleeves is released (use a piece of pipe between the axle and the mallet/hammer not to damage the threads). Remove the sleeve with a plier.

Mount a short bolt and remove the axle using a sliding hammer, puller or similar. Bolt is normally fine pitch and sold by your dealer.