First Fit Installation

Instruction for Straight Pin with Mounting Tool

2.1

Follow the installation instructions to ensure that the Expander System is installed correctly and to prolong the pivot life.

Expander System pivot pin comes with a warranty against lug wear of 10 years / 10 000 hours in operation (whichever comes first) from the date of purchase.

This instruction is valid for lug holes with the following maximum tolerances:

- Hole tolerances: H9

- Lug hole inner surface roughness: Ra 3.2

- Misalignment of lugs: Outer lug distance/500

- There should be no bushings in the lug ears

If your lugs are not within these specifications, please consult your dealer or Expander System for installation recommendation.

1. Bolt 2. Washer 3. Sleeve 4. Axle (Pin) 5. Bolt for mounting tool 6. Stop screws

7. Mounting tool 8. Allen key screws

The picture shows a female axle but the principle is the same for other designs.

Installation

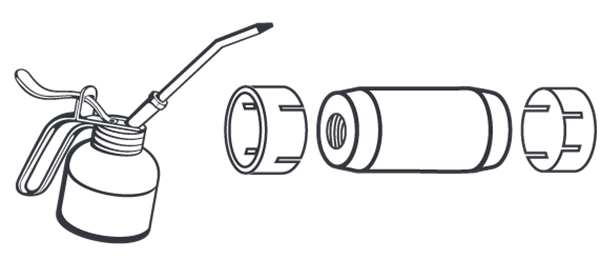

Grease the sleeves and axle, preferably graphite grease.

NOTE! If applicable: position greasing outlet 90 degrees to force direction to minimize stress concentration at outlet.

Assemble the mounting tool and bolt for mounting tool using the allen key screws. Insert the axle and position it in the bores. Install the sleeves, then the washers and fasteners. Tighten the fasteners with recommended torque.

Remove the allen key screws and mounting tool. Mount the stop screws.

Torque recommendations

Hex Bolts and Bolts for Mounting Tool

Torques M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 70 | 115 | 175 | 350 | 500 | 600 | 700 | 900 |

| lb-ft | 52 | 85 | 129 | 258 | 369 | 443 | 516 | 664 |

Hex Nuts: Standard Height

Torques M12-M24 ± 10%, M30... +30/-0%

| M12 | M14 | M16 | M20 | M24 | M30 | M36 | M42 | |

| Nm | 65 | 115 | 175 | 250 | 350 | 500 | 600 | 700 |

| lb-ft | 48 | 85 | 129 | 184 | 258 | 369 | 443 | 516 |

Hex Nuts: Low Height

All Torques ± 10%

| M12 | - | M16 | M20 | M24 | M30 | - | - | |

| Nm | 60 | - | 125 | 200 | 275 | 350 | - | - |

| lb-ft | 44 | - | 92 | 148 | 203 | 258 | - | - |

Spanner Nuts

All Torques ± 10%

| M17 | M25 | M35 | M45 | M55 | M65 | M75 | M85 | |

| Nm | 50 | 120 | 250 | 500 | 600 | 700 | 800 | 900 |

| lb-ft | 37 | 89 | 184 | 369 | 443 | 516 | 590 | 664 |

Final check

After initial torque, grease the pivot (if applicable), move the machine through full range of motion several times and recheck the torque. Check the torque after 10 hours, 40 hours and at regular service intervals to ensure proper seating of the sleeves.

Ensure that there is a minimum distance of 0,5mm (0.02”) between the washer and the lug. Ensure that there is a minimum distance of 0,5mm (0.02”) between the bolt for the mounting tool and the lug. ATTENTION! If the washer or bolt for the mounting tool is in contact with the lug, contact your dealer or Expander System.