From the food we eat and the clothes we wear, to the transport we use and buildings we live and work in – just about everything we see and touch everyday has gone through a manufacturing or processing plant. In factories and warehouses all over the world, a vast array of materials and goods are produced and packed, with increasingly advanced and sophisticated machinery.

Automation is key for a quick and reliable process, which gives cost effectiveness and profitability. Processes are therefore planned down to the smallest detail to ensure that nothing can go wrong. One thing all manufacturing and processing equipment shares is the need to be in constant motion. One fault or breakdown can cease productivity for the whole line, and every minute of downtime is costly. This is especially true for bolted joints as wear or loosening can come at a significant cost.

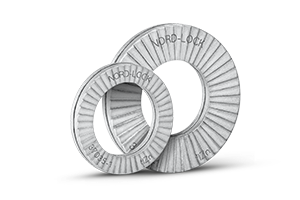

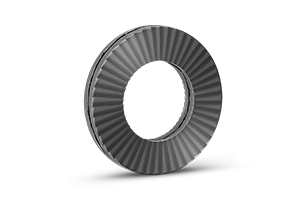

Regardless of the conditions and demands, all connections need to stay locked, but still allow for effective regular maintenance. Today, Nord-Lock Group products are used in countless manufacturing and processing machines all over the world. Many customers have come to appreciate their strong locking capabilities along with their ability to withstand extreme conditions, which has resulted in reduced maintenance and repairs, and lower life-cycle costs.