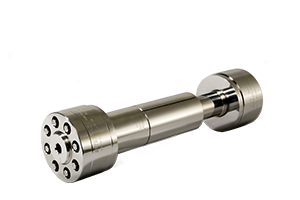

Superbolt is adding the New HyFit to its range of expansion bolt products. The launch further strengthens Nord-Lock Group ability to supply a complete range of tensioning solutions for any coupling bolt challenges.

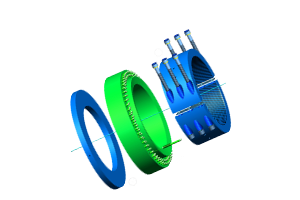

The New Superbolt HyFit system has been conceived to eliminate the need for an internally connected thread puller. It uses a threaded connection of larger diameter than the bolt, making it far safer to use than any existing hydraulic coupling bolt design.

Traditional, ‘fitted’ bolts reduce in diameter when tightened, leaving clearance and the possibility of coupling slippage under shock loading. This can lead to difficulty in removal, resulting in coupling hole and bolt damage and causing outage delays and expensive repair work.

Hole and bolt damage can lead to days of unplanned work, meaning loss of availability and additional high-cost critical downtime.

Superbolt HyFit expansion bolts prevent all of these issues because they are installed and removed in clearance conditions.