| Toepassingsparameter | ||||

| Staal | Roestvrij staal RVS | 254 SMO® | INCONEL®/ HASTELLOY® C-276 | INCONEL® 718 |

| Staalsoort | ||||

| EN 1.7182 | EN 1.4404 | EN 1.4547 | EN 2.4819 of gelijkwaardig | EN 2.4668 of gelijkwaardig |

| Voorbeelden van toepassingen | ||||

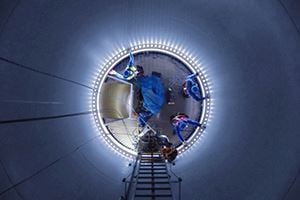

| Algemene staaltoepassingen | Algemene RVS-toepassingen. Niet chloorhoudende of zure omgevingen | Algemene zoutwatertoepassingen, pompen, chloridetoepassingen, warmtewisselaars, nucleaire-, ontziltings-, voedselverwerkende en medische apparatuur | Algemene zure omgevingen, proces- en chemische industrie, verdampers, offshore-boorgereedschappen | Toepassingen met hoge temperaturen, gasturbines, turbo's, verbrandingsovens |

| Beschikbaar voor boutmaten | ||||

|

M3-M130 #5 to 5" |

M3-M80 #5 to 3 1/8" |

M3-M39 #5 to 1 1/2" |

M3-M39 leverbaar op aanvraag #5 to 1 1/2" leverbaar op aanvraag |

M3-M39 leverbaar op aanvraag #5 to 1 1/2" leverbaar op aanvraag |

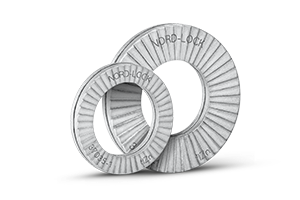

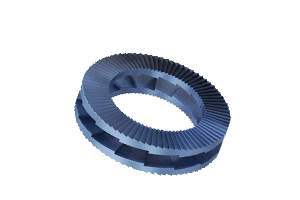

| Borgringtypes | ||||

|

Standaard buitendiameter (NL3 - NL130) Grotere buitendiameter (NL3,5sp - NL36sp) |

Standaard buitendiameter (NL3ss - NL80ss) Grotere buitendiameter (NL3,5spss - NL30spss) |

Standaard buitendiameter (NL3ss-254 - NL39ss-254) Grotere buitendiameter (NL3,5spss-254 - NL27spss-254) |

Standaard buitendiameter (NL3ss-276 - NL39ss-276) Grotere buitendiameter (NL3,5spss-276 - NL27spss-276) |

Standaard buitendiameter (NL3ss-718 - NL39ss-718) Grotere buitendiameter (NL3,5spss-718 - NL27spss-718) |

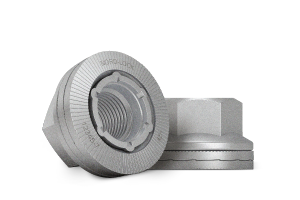

| Behandeling / oppervlaktecoating | ||||

| Doorgehard Delta Protekt® basiscoating (KL100) en topcoating (VH302GZ) | Oppervlaktegehard | Oppervlaktegehard | Oppervlaktegehard | Oppervlaktegehard |

| Borgringhardheid* | ||||

| ≥ 465HV1 | ≥ 520HV0,05 | ≥ 600HV0,05 | ≥ 520HV0,05 | ≥ 620HV0,05 |

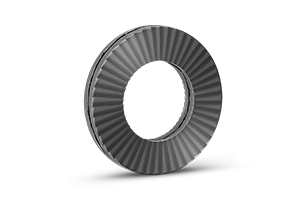

| Corrosiebestendigheid | ||||

| Minimaal 600 uur in zoutneveltest (volgens IS09227) | PREN 27** | PREN 45** | PREN 68** | PREN 29** |

| Boutkwaliteiten | ||||

| Tot 12.9 | Tot A4-80 | |||

| Temperatuurbereik*** | ||||

| -50°C - 200°C | -160°C - 500°C | -160°C - 500°C | -160°C - 500°C | -160°C - 700°C |

* Om de unieke mechanische borgwerking van de Nord-Lock borgringen te garanderen moet de hardheid van de contactvlakken lager zijn dan die van de Nord-Lock borgringen.

** PREN (Pitting Resistance Equivalent Number) = % Cr + 3,3x% Mo + 16x% N. Gegevens in de tabel gelden voor het basismateriaal.

*** Aanbevolen temperaturen gebaseerd op informatie van de grondstofleverancier. Borgende werking niet aangetast binnen de specificatie.