Are Nord-Lock Wedge-Locking Washers Reusable?

The short answer is, yes. You can normally reuse Nord-Lock wedge-locking washers, but it is necessary to perform a thorough inspection of both washers in the pair for signs of damage first. Damaged or worn washers should not be reused, as this can limit the performance of the wedge-locking effect and expose your bolted joints to loosening.

Since Nord-Lock is a removable system, assemblies secured by the wedge-locking washers can easily be dismantled with a torque wrench. Untightening Nord-Lock washers is as simple as tightening. Note that since the locking function is not based on increased friction, the untightening torque is generally lower than the tightening torque.

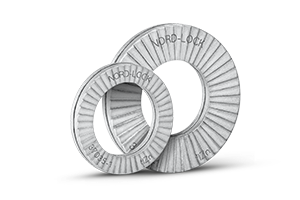

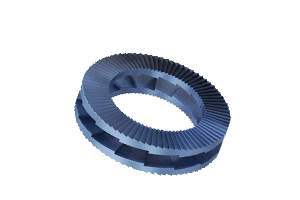

The pre-assembled washers are installed in pairs, cam face to cam face. After their first use, the pre-assembling glue is no longer effective, and the washer pair comes apart.

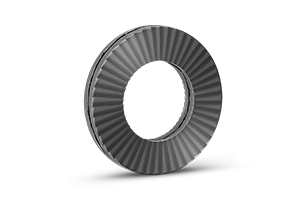

Before remounting, control the reusability of each component of the assembly, including the Nord-Lock washers. Check that the cams on the inside of the washers are not completely worn, rusted or partially damaged, then proceed to check the serrations on the reverse side.

Once the components have been inspected, the assembly can be remounted and reused. Make sure that the washers are reinstalled correctly, cam face to cam face with the serrations on the outside.

How many times can a Nord-Lock washer be reused?

There is no definitive answer as to how many times you can reuse the washers. Quite simply, you should review the condition of both washers in the pair each time you disassemble the application and wish to reuse them.

There are however steps you can take to increase the likelihood that your washers remain in good condition and can be reused. Nord-Lock recommends the use of a high-quality, anti-seize lubricant to minimize changes in friction conditions and improve tightening.

Lubrication is especially beneficial for large sized bolts and stainless-steel applications. Although Nord-Lock's wedge-locking function provides safe locking in both dry and lubricated conditions, the benefits of lubricated fasteners include:

- Improved reusability

- Reduced friction and deviation

- Facilitated assembly and disassembly

- Reduced torsion stress due to minimized thread friction

- Avoided galling and thread seizure

- Additional protection against corrosion

For more technical support with wedge-locking washers or any bolting technologies, talk to an experienced Nord-Lock engineer at any one of our global Technical Centers now