| Parametri di applicazione | ||||

| Acciaio | Acciaio inossidabile (ss) | 254 SMO® | ALLOY C-276 |

ALLOY 718 |

| Tipo di acciaio | ||||

| EN 1.7182 | EN 1.4404 | EN 1.4547 | EN 2.4819 o equivalente | EN 2.4668 o equivalente |

| Esempi di applicazione | ||||

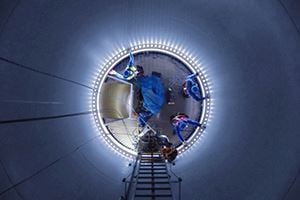

| Applicazioni comuni in acciaio | Applicazioni comuni in acciaio inossidabile. Ambienti non acidi e senza cloro | Applicazioni comuni in acqua salina, pompe, applicazioni con cloro, scambiatori di calore, nucleare, desalinizzazione, industria alimentare e attrezzature mediche | Ambienti acidi comuni, industria chimica e di processo, evaporatori, perforazioni offshore | Applicazioni ad alte temperature, turbine a gas, turbocompressori, inceneritori |

| Disponibile per bulloni | ||||

|

M3 - M130 #5 - 5" |

M3 - M80 #5 - 3 1/8" |

M3 - M39 #5 - 1 1/2" |

M3 - M39 disponibile su richiesta #5 - 1 1/2" disponibile su richiesta |

M3 - M39 disponibile su richiesta #5 - 1 1/2" disponibile su richiesta |

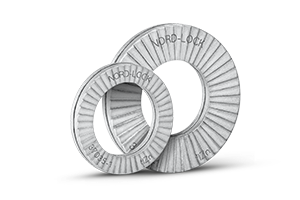

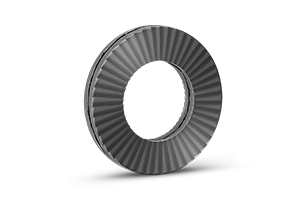

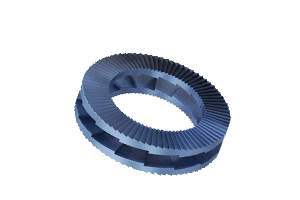

| Tipo di rondelle | ||||

|

Diametro esterno regolare (NL3 - NL130) Diametro esterno maggiorato (NL3,5sp - NL36sp) |

Diametro esterno regolare (NL3ss-NL80ss) Diametro esterno maggiorato (NL3,5spss - NL30spss) |

Diametro esterno regolare (NL3ss-254 - NL39ss-254) Diametro esterno maggiorato (NL3,5spss-254 - NL27spss-254) |

Diametro esterno regolare (NL3ss-276 - NL39ss-276) Diametro esterno maggiorato (NL3,5spss-276 - NL27spss-276) |

Diametro esterno regolare (NL3ss-718 - NL39ss-718) Diametro esterno maggiorato (NL3,5spss-718 - NL27spss-718) |

| Trattamento / Rivestimento superficiale | ||||

| Temprato in profondità Delta Protekt® base coat (KL100) and top coat (VH302GZ) | Superficie indurita | Superficie indurita | Superficie indurita | Superficie indurita |

| Durezza delle rondelle* | ||||

| ≥ 465HV1 | ≥ 520HV0,05 | ≥ 600HV0,05 | ≥ 520HV0,05 | ≥ 620HV0,05 |

| Resistenza alla corrosione | ||||

| Minimo 1,000 ore nel test in nebbia salina (in conformità a IS09227) | PREN 27** | PREN 45** | PREN 68** | PREN 29** |

| Grado di resistenza dei bulloni | ||||

| Fino a 12.9 | Fino a A4-80 | |||

| Range di temperatura*** | ||||

| Da -50°C a 200°C | Da -160°C a 500°C | Da -160°C a 500°C | Da -160°C a 500°C | Da -160°C a 700°C |

* Per garantire la funzione bloccante meccanica unica delle rondelle Nord-Lock, la durezza delle superfici di appoggio deve essere inferiore a quella delle rondelle Nord-Lock (vedi tabella sopra).

** PREN (Pitting Resistance Equivalent Number / Indice di resistenza alla corrosione da vaiolatura)) = %Cr + 3,3x%Mo + 16x%N. . I dati nella tabella si riferiscono al materiale di base.

*** Le indicazioni sulle temperature sono basate sulle informazioni ricevute dal fornitore della materia prima. La funzione bloccante non è pregiudicata entro le specifiche.