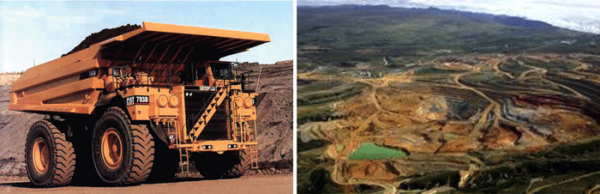

MINING OPERATIONS: SAFE, PRODUCTIVE AND COST-EFFECTIVE SOLUTIONS

A high-stakes industry with no room for errors. Nord-Lock Group provides industry-leading bolting and engineering solutions for safe, cost-efficient, and time-saving mining operations.

Extracting modern-day essential minerals and materials, whether underground or at surface level, is challenging work. It requires heavy, expensive machinery and skilled operators working in accident-prone environments. Streamlining maintenance, mitigating downtime, and keeping operators safe are non-negotiable top priorities.

The path to safe, productive mining involves ensuring the use of reliable and durable critical components. These are the ones that keep machines running and save valuable time on rebuilds and regular service maintenance.