Getting the best of both worlds

On the face of it, building the Kienlesberg bridge was a real-life mission impossible. After all, how can you successfully bring together two completely opposing concepts?

Located in Ulm, between the southern German cities of Stuttgart and Munich, the Kienlesberg bridge was to become a beautiful example of filigree architecture.

Stretching 270 metres in a smooth curve, this work of art was to feature specially-fitted vantage points. Here, pedestrians and cyclists could pause to behold the historic city below them, and especially the glorious Gothic style Minster church, which boasts the world’s tallest steeple.

At the same time, however, everything had to be about rules and reliability, safety and sturdiness. Requiring over 2,500 tonnes of steel, this construction had to be robust enough to support two train tracks.

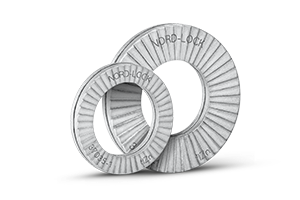

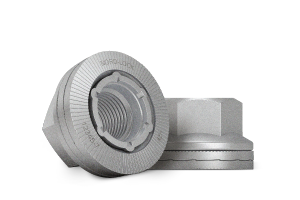

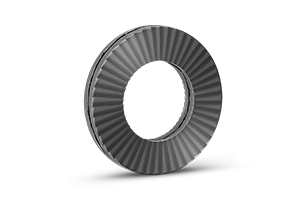

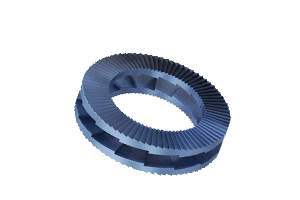

Moreover, with a bustling Deutsche Bahn intersection below, the bridge meant complying with strict and uncompromising safety regulations. The endless rules governed everything from electrical cables to train tracks. Despite the seemingly impossible nature of the challenge, the solution came in the form of a dream-team combination of two products. This included glass-fibre reinforced plastics (GRP) from CTS (Composite Technologie Systeme GmbH), and special washers from the Nord-Lock X-series bolt securing system.

There are two main reasons why Nord-Lock products were a perfect fit for this project. Severe vibration from rattling carriages on a high-speed train can lead to bolt loosening, but not when used with Nord-Lock X-series washers. The wedge-effect underneath the bolt head and nut means the washers cannot loosen unintentionally.

CTS found Nord-Lock washers to be highly reliable as they also passed Deutsche Bahn’s strict safety tests. CTS could now guarantee that their product – fitted using Nord-Lock washers – could withstand the vibration.

Customer: CTS COMPOSITE TECHNOLOGIE SYSTEME GMBH

Project: KIENLESBERG BRIDGE, ULM, SOUTHERN GERMANY

Challenge: BOLT-LOOSENING DUE TO VIBRATION

Solution: NORD-LOCK X-SERIES WASHERS

Steel used: OVER 2,500 TONNES