The Experts: Thread engagement in a tapped hole

What is the recommended thread engagement to make a strong connection for a component with a tapped hole?

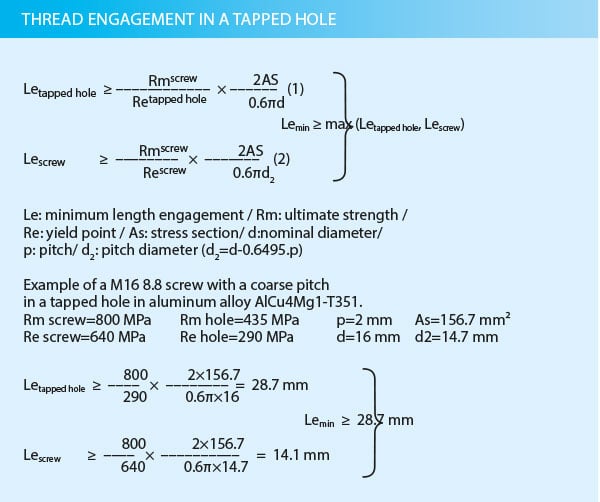

Basic design rules require the bolted joints to be designed so that the screw breaks before the threads strip. For components with tapped holes the length engagement (i.e. the number of threads which are engaged between the screw and the tapped hole) has to be adapted to respect this criteria.

The critical areas of stress are as follows: tensile stress area of the bolt, stress area of the male thread, and stress area of the female thread.

The critical areas of stress are as follows: tensile stress area of the bolt, stress area of the male thread, and stress area of the female thread.

It is commonly known that the minimum recommended thread engagement to make a strong connection for a component with a tapped hole is approximately 1 times the nominal diameter in steel and 2 times the nominal diameter in aluminum. In many cases, (tapped hole in a softer material, special alloys, etc.) these values are not sufficient and the formulae to the right must be applied.

These formulae are simplified and give only an estimation. Calculating the precise required thread engagement is a very complex issue that had been studied by E.M. Alexander who had defined an analytical formula taking into accounts all parameters.

When analytical calculation gets more complicated, a Finite Elements Analysis can be performed.

Do you have a question about bolt securing?

Put the Nord-Lock experts to the test.

Email your questions about bolt securing to

experts@nord-lock.com