First-fit Design for Original Equipment Manufacturers (OEM)

Personalization in every pin - we design and manufacture to your exact tolerances and requirements, eliminating a weak link in the machine so it can perform for longer, exactly as it was built to.

"Whatever your machine, industry or application, we will create the perfect pivot pin for you"

HIGH PERFORMANCE

Power your machine to perform like it was built to. The sleeves expansion in the bore eliminates play and redistributes the load. Prevent lug wear from the first installation, minimize unwanted movement and reduce the overall bearing/pivot wear.

FOR ANY REQUIREMENTS

With no one-size-fits-all approach to high performance parts, we engineer (and re-engineer) tailored solutions to overcome heavy industry's pin problems. As the first-to-market with more than 40 years of experience, we make it easy to build new machines with world-class pins. Best-in-class test centers validate the performance of Expander products under real world conditions.

VALUE ADDING

Use Expander System to build value-added models with a lower total lifecycle cost. Switching to first-fit streamlines your assembly process and lowers the total build cost. Listing Expander as an aftermarket wear part gives your customers choice, and you an additional revenue stream. Plus, a longer lasting pin system improves the sustainability profile of your machines.

Quality assurance

Manufactured in the US & Europe, distributed globally. Our production facilities are equipped to enable high-speed manufacturing and delivery of complete pivot assemblies. We invest in the latest production technology to ensure maximum capability and quality, and we produce all parts of the Expander System.

QUALITY & MANUFACTURING

CERTIFICATION

Based on your needs, we deliver certificates and perform testing. For example, certificates according to EN10204 or Ultrasonic-, Magnetic particle- and Charpy testing.

QUALITY

Our production facilities around the world are equipped to enable high-speed manufacturing and delivery of complete pivot assemblies. We invest in the latest production technology to ensure maximum capability and quality, and we produce all parts of the Expander System.

TRACEABILITY

Expander System pins are marked with a lot number to track exactly where the steel originates and when it was made. As a manufacturer, you also have the opportunity to mark Expander axles with your brand to show your customers that you take pride in the details.

Certificates and approvals

Expander System is approved, installed and listed in spare parts by the world's leading equipment manufacturers.

DESIGN SUPPORT

We have extensive technical knowledge in design, tolerances, and the correct material. Customization options include materials, hardening treatments, surface coatings and tolerances. We can design to precise customer specifications i.e., marine grade stainless steel.

TESTING & VALIDATION

From structural strength calculations to the dimensioning and production of your complete pivot pin axle – our personalized service will accompany you throughout the pivot pin creation process.

CO-BRANDING

Get co-branded marketing materials to support aftermarket sales. Plus, mark the axles with your company logo and offer your end users the premier solution for pin replacements.

CUSTOMER SUCCESS STORIES

A Pin Upgrade for Kafril Group’s Hitachi Demolition Excavator (‘Beast of the East’)

See how Kafril Group upgraded their Hitachi Demolition Excavator with Expander System pivot pins to minimize wear and stay competitive.

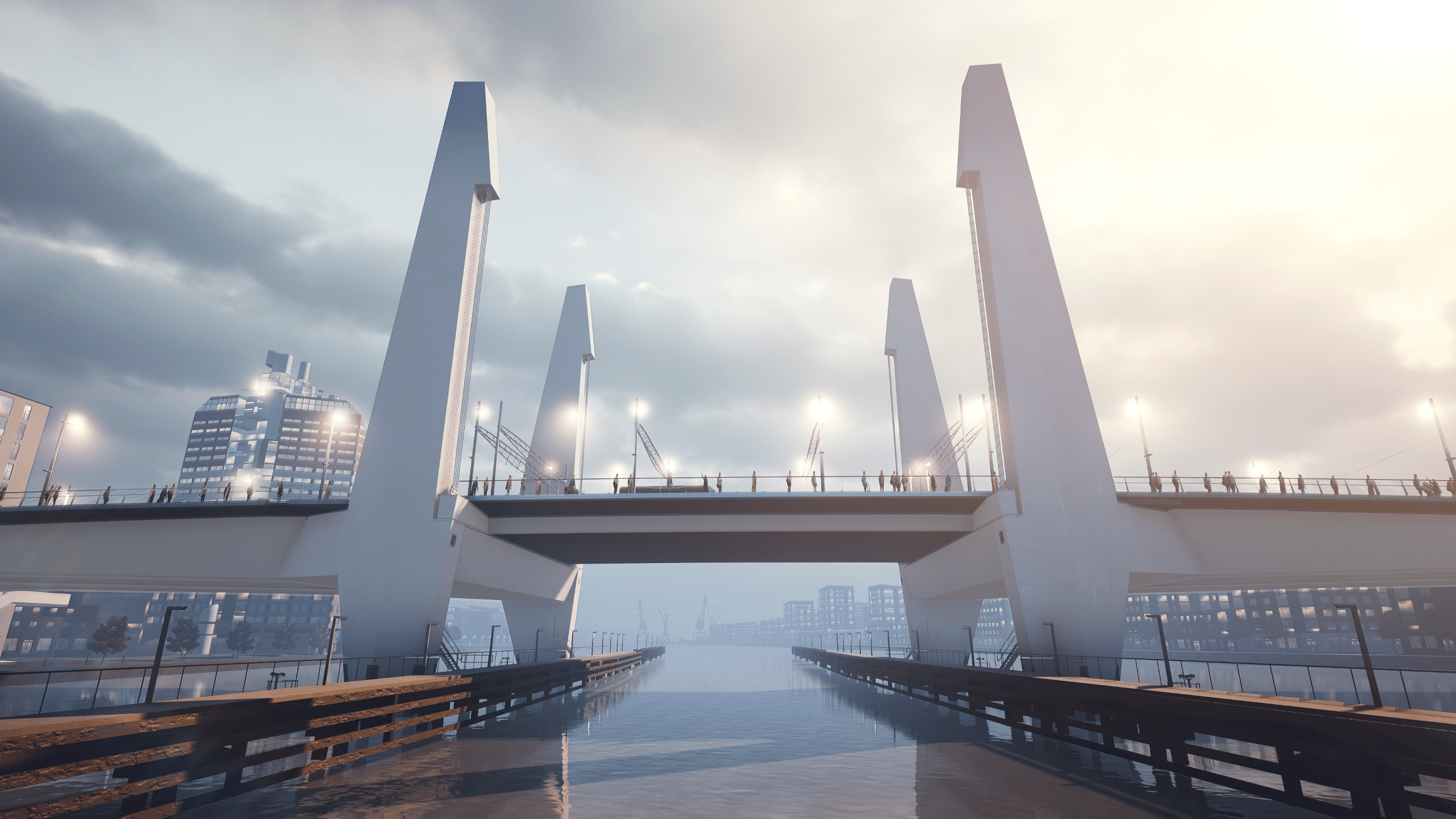

Expander System pivot pins perfect for complex bridge design

Custom Expander axles secure critical pivot joints, giving precision and reliability to raise/lower the Hisings Bridge in Sweden for ships to pass underneath.

Steering pins replaced fast

The challenge A mining company in Canada needed a better solution for replacing the steering pins on its fleet of one hundred Komatsu trucks. With the traditional method, replacing the pins took aro...

Expander System passes 50 000h of testing with flying colors

The Expander System was field tested in the steering cylinder position on Volvo BM 4300 wheel loaders through four machine lives in Sweden over a period of six years.

Secure machinery for the toughest forestry harvesting

Find out how this global supplier of forestry grapple harvesters builds robust and flexible machinery that will survive even the toughest of forest harvesting.