Lock and throw away the key – Bolting behind closed doors

In most cases when bolts come loose, we can tighten them. But what if they are impossible to access and must maintain a specific preload? A glass roof inside a newly developed quarter in the heart of Hamburg presented the developers with these challenges.

Nord-Lock washers secure a magnificent piece of architecture

Right next to the Elbe River in Hamburg, integrated into the urban development project HafenCity, sits the Westfield Hamburg-Überseequartier. Developed by the company Westfield with a strong focus on sustainability, the district hosts offices, restaurants and just about every other facility essential for a modern, buzzing city center.

Walking through the Hamburg Überseequartier, visitors are immediately struck by its unique architectural character. However, standing out is an inner glass roof, designed by renowned German star architect Werner Sobek. Assembled with thousands of unique panels, the roof resembles something straight out of a sci-fi movie and appropriately captures the Hamburg-Überseequartier’s identity of a forward-thinking, urban environment.

2024 Roschmann. All rights reserved

2024 Roschmann. All rights reserved

The glass façade specialists for steel constructions, Roschmann Group, whose work includes the headquarters of the International Olympic Committee in Lausanne and the Eifel Tower’s visitor center, was tasked with turning Werner Sobek’s vision into reality.

If the roof’s grandeur is obvious at first glance, the bolting challenges involved in realizing it are far from it.

The multiple benefits of bolted connections

Other than the uniquely shaped panels, the roof structure is made up of hollow sections, which is ideal for wide-spanning structures where strength, stability, low weight, and aesthetics are of highest priority.

After initially having considered welded nodes as the fastening solution, Roschmann realized the rather insurmountable challenges it would imply, and decided to throw bolted connections into the mix.

“Using welded nodes exclusively would have been highly complex and time-consuming, requiring a lot of assembly work on the construction site and auxiliary connections”, says Michael Skopp, Head of Research and Development and René Hesselbarth, Project Manager at Roschmann.

2024 Roschmann. All rights reserved

2024 Roschmann. All rights reserved

The advantages of bolted connections were several. Firstly, the time-effectiveness it brought was key for Roschmann in acquiring the project. Secondly, when not every single connection had to be assembled on site, separate sections of the roof could be constructed off-site, which made for smoother logistics and coordination. But the most advantageous upside of using bolted connections was flexibility.

“The roof segments weigh several tonnes and had to be lifted into place using a construction crane. With welded connections, it is no longer possible to check and correct the positioning of the segments once they have been assembled. But with bolted connections, we were able to re-work and fine-tune the positioning which gave us crucial flexibility,” says Michael Skopp and René Hesselbarth.

A roof that moves

The ability to readjust and torque to exact predetermined preload values was also necessary for the roof to be able to move slightly. For that end, Roschmann turned to The Center of Competence for Tubes and Hollow Sections (CCTH), an engineering company specializing in hollow section applications, to calculate the preload that would allow for it.

“The entire structure relies heavily on highly specific, predetermined preload intervals” says Dr.-Ing Stefan Herion, Managing Director at CCTH. “So, because we had to allow for slight movements in the construction, we had to preload the bolt with just the right levels.”

After having identified the necessary preload force ensuring that the nodes in the roof construction would bear as they should, while also allowing for some degree of movement, the next step was to ensure that the preload was applied accurately. Therefore, tightening tests were carried out by the Munich University of Applied Sciences.

Also working together with Roschmann and CCTH to identify a solution that would maintain the bolted connections torque and preload behavior was the bolt manufacturer August Friedberg GmbH. The German company provides bolting solutions to numerous industries, and in this project, it consisted of a highly sophisticated lubrication system.

“Our job was to find a lubricant that would make it possible to achieve a certain preload in the bolting solution, that would also remain stable over time with low scatter” says Dr.-Ing. Selcuk Güres, Head of Research and Development at Friedberg.

2024 Roschmann. All rights reserved

2024 Roschmann. All rights reserved

Friedberg used their newly developed AF Pro lubrication, which, in addition to meeting all the requirements related to torque and preload behavior, is also able to withstand environmental challenges related to Hamburg’s humid, rainy sub-oceanic climate. Moreover, since the number of nuts and bolts exceeded 5000, in a range of different sizes, standard partial lubrication of relevant head and thread surfaces would have taken up too much time. Therefore, Friedberg came up with a special, automated solution that lubricated the entire bolt.

Bolting out of the ordinary

The bolting challenges in the roof construction were, for various reasons, unique and tricky. As previously mentioned, the calculated preload necessary to allow the roof to be flexible enough to allow for small movements did not fall within the regulative levels as its neither preloaded nor non-preloaded.

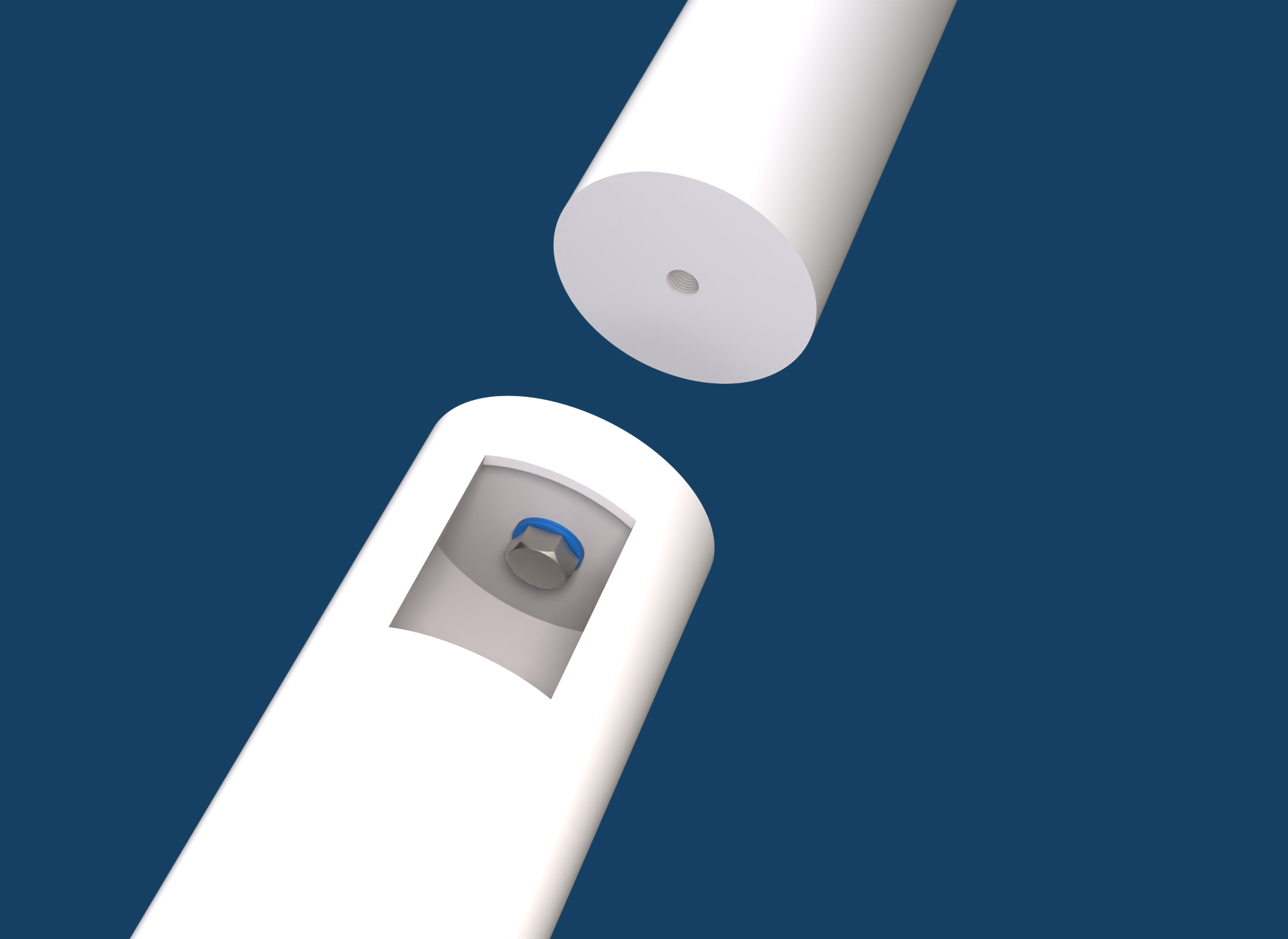

Another detail making the bolting challenging and not compliant with regulated, standardized protocols, was the combination of parts (i.e., bolt and washer) assembled inside the hollow sections, also called “blind hole connection”, meaning that the bolted connections are not visible. In the roof construction, the connections were covered with clipped plates.

“The blind-hole connection was crucial for the aesthetics of the roof. Standing underneath, you cannot really see how the whole structure is fixed together since there are no signs of welding or visible bolts or nuts.” says Stefan Herion.

2024 Roschmann. All rights reserved

2024 Roschmann. All rights reserved

The combination of not fully preloaded bolted connections and blind hole connections using a single longitudinal bolt, was an unprecedented construction challenge to Stefan Herion and his colleagues.

Also, for Friedberg, a couple of aspects made working on the roof-construction project something quite out of the ordinary:

“Usually, German steel construction standards regulate what bolts you can use with what nuts and in what type of connections. In this case, the combination of fully lubricated HV bolts together with wedge-locking washers installed in a threaded blind-hole by torquing the bolt head is probably as far from standard as it gets” says Dr.-Ing. Selcuk Güres.

A closer look at the blind hole connection in the roof construction. On the opposite side of the hollow section, the bolted connection anchors into a solid material structure, rather than another hollow section.

A closer look at the blind hole connection in the roof construction. On the opposite side of the hollow section, the bolted connection anchors into a solid material structure, rather than another hollow section.

For Friedberg, to understand the relation between torque and preload and how to optimize the use of lubrication meant extensive testing with all components to be used in the final roof application

So, from all of this follows a critical question: since the bolted connections are located in sealed blind-holes directly underneath massive glass panels, how does maintenance work? The answer to that question is: it doesn’t.

Standing out in a crowd of bolt-securing methods

With no possibility of accessing the bolted connections, Roschmann needed to ensure that preload would remain within the calculated intervals. So, essentially, they needed a maintenance-free bolting solution that could handle the roof’s non-standardized, not fully preloaded connections determined by CCTH and Roschmann. From these challenging prerequisites, Stefan Herion at CCTH instinctively thought of Nord-Lock.

“My first encounter with Nord-Lock washers was watching a video of the junker test, which clearly demonstrated the washers capability of maintaining preload levels under severe vibrations.” says Stefan Herion.

Since then, Stefan Herion has collaborated with Nord-Lock on numerous construction projects and, each time, become more reassured of the washers capability of safeguarding the integrity of complicated and critical constructions. In this project, which clearly did not follow standard protocols and made necessary a very specific preload, the bolt-securing method needed to make absolutely sure that it would remain stable once installed.

2024 Roschmann. All rights reserved

2024 Roschmann. All rights reserved

Together with responsible proof engineers and Roschmann, Stefan and his colleague Dr.-Ing Oliver Fleischer discussed the bolting alternatives at hand: Proceeding according to standard protocols was not an option since the roof, as mentioned, needed a certain degree of flexibility to move. Another option, applying glue to maintain preload, is not a regulated method in the construction industry, and would also not have allowed for readjustments during assembly. So, in light of such shortcomings of other bolt-securing methods, Nord-Lock washers emerged as the optimal solution.

“The discussion was a rather quick one. What we needed was a solution that would maintain a preload high enough to press surfaces together. Just a little loss in preload would result in splitting and potentially serious negative consequences. Using Nord-Lock washers was also the only solution that allowed for un-torquing, which was crucial to set the preload just right and assemble the roof correctly” Michael Skopp and René Hesselbarth.

Just like CCTH, Roschmann had previously turned to Nord-Lock washers for their glass façade projects. The roof at the Hamburg Überseequartier turned out to extend the list.

A bolting partner in turning theory into practice

Identifying just the right bolting solution, including preload levels, lubrication, and securing-method, was key in turning Weber Sobek’s vision into a real-life, safe, and robust construction set to last for decades.

As illustrated in every step of this story: behind the scenes of the awe-inspiring experience of standing underneath the roof, there’s an entire apparatus of calculations and testing making it possible. This relationship between hardcore engineering, mathematical theory, and the very real construction it resulted in is what both Michal Skopp and René Hesselbarth singles out as the most rewarding aspects with this project:

“When we were closing in on the project, I stepped out on the roof. Then, one of the construction workers joined me and I could feel the roof move as he walked. And just knowing that all of these calculations and assumptions made it possible – that’s very cool.”

2024 Roschmann. All rights reserved

2024 Roschmann. All rights reserved

But besides the engineering itself, for time-pressured projects at this scale to run smoothly and turn out as planned, Roschmann emphasizes the crucial need for short ways of coordination.

“There simply isn’t much time, which means that effectiveness is everything. That was also a decisive reason why we chose Nord-Lock. Not only did we know that their washers would be able to meet all of the roofs unique requirements, but we’ve come to know them as a highly collaborative and quick-responding partner.”