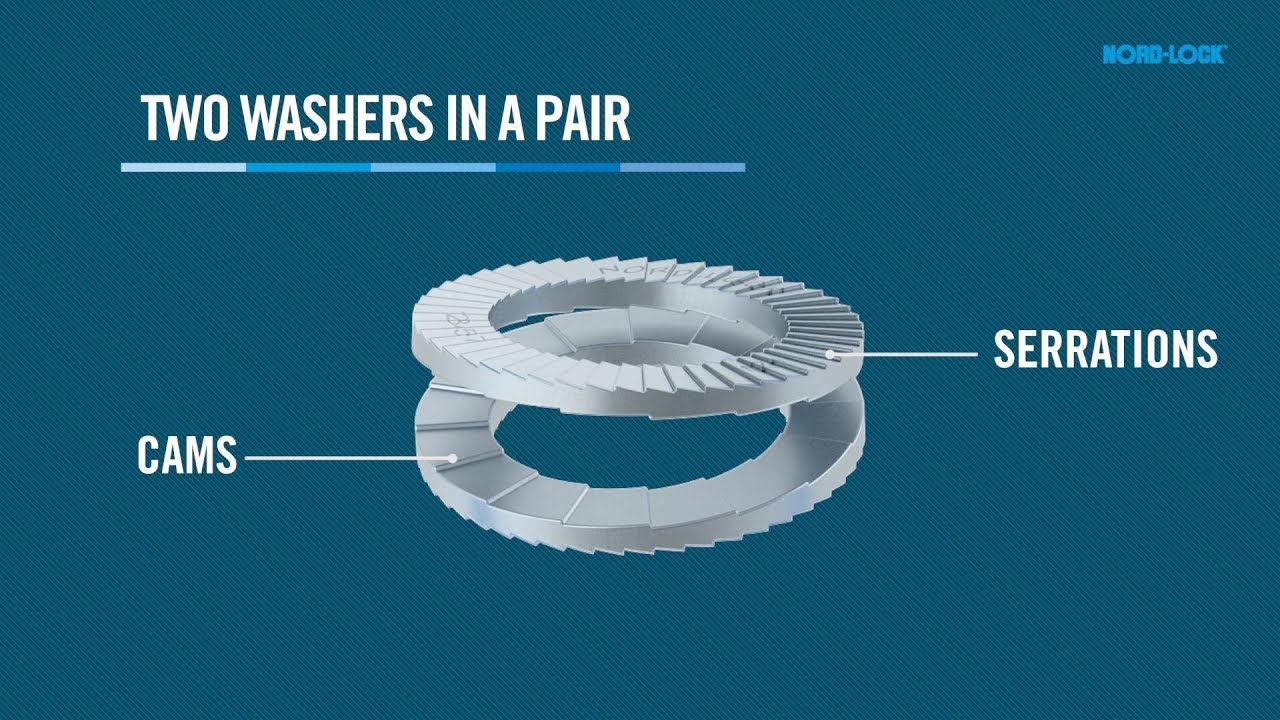

Nord-Lock's original wedge-locking technology

The wedge-locking technology of our washers truly is a high point of engineering. Every detail matters in keeping bolts tight and secure, even under extreme vibrations and dynamic loads.

TIGHTENING

When the bolt and/or nut is tightened, the serrations grip and seat the mating surfaces. The Nord-Lock wedge-locking washer is locked in place, allowing movement only across the face of the cams.

Since the cam angle α, is larger than the thread pitch β, a wedge effect is created by the cams, preventing the bolt from rotating loose. Any attempt from the bolt/nut to rotate loose is blocked by the wedge effect of the cams.

UNTIGHTENING

When the fastener is untightened, sliding will occur between the two washers. The upper washer is locked to the nut or bolt head by the serrations. The lower washer does not rotate as its serrations are locked into the surface being clamped.

As the cams slide over each other, the clamping load from the bolt is first increased as the bolt stretches, before being released as the cams pass each other.

Specifications

Standard range bolt sizes M3 - M130

Five different materials - steel, stainless steel, 254 SMO, alloy 718 and alloy C-276

SP washers with enlarged outer diameter

Secure bolts reliably at high and low clamp loads

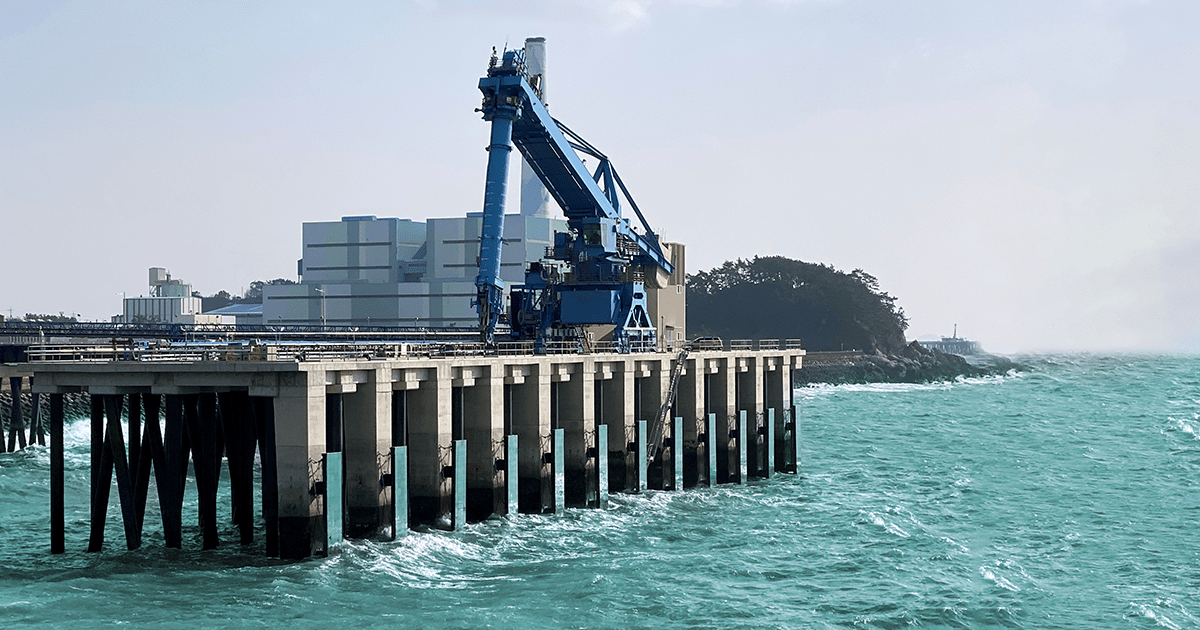

Steel construction washers for steel constructions applications

Nord-Lock washers are included in our wheel nut and combi nut products