The holy grail of jackbolt tensioning

Since the launch of the Superbolt Multi-Jackbolt Tensioner (MJT) in 1984, efforts have been made to constantly improve efficiency. One suggestion came up regularly - to tighten multiple jackbolts simultaneously.

The consensus was that this idea was technically and cost effectively extremely difficult to develop, until an inventor from Australia inadvertently built the technology that would change the course of jackbolt tightening forever.

In 2014, Andy McPhee visited his friend and fellow inventor, Peter Armstrong. He found Armstrong hunched over the kitchen table working on a design for a continual motion tool that could replace a traditional hydraulic torque wrench. McPhee looked over his friend’s shoulder and, always full of ideas, made a few suggestions. Since Armstrong did not have the CAD capabilities to implement them, McPhee offered to help.

“I used to have my own company, which supported crazy mad inventions,” explains McPhee. “We helped people with wonderful ideas bring them to the market. I’ve also invented many things, I get real pleasure out of creating things and seeing them come to life.”

The idea was exactly what the industrial sector needed and it was not long before outside interest started to grow. In January 2015, as the pair were finalizing the drive technology for a potential investor, they got a call from an old contact who worked for Nord-Lock Group and invited him to take a look.

Little did they know that this was exactly what Nord-Lock Group had been waiting for – a compact drive mechanism that could generate enough torque required to tighten multiple jackbolts simultaneously. At this time, a very conceptual model was unveiled to show how the drive, powered by what they were calling ‘scroll drive technology,’ could be utilized. Soon, McPhee and Armstrong were officially developing the new Superbolt Tool for Nord-Lock Group.

Overcoming technical challenges

Although McPhee and Armstrong were on the right track, there were still challenges on the horizon. Indeed, how do you develop something that is potentially impossible to create? “It’s sort of been a holy grail to see if someone could figure out how to tighten multiple jackbolts simultaneously,” explains Steve Greenwell, Director of Tensioning Division at Nord-Lock Group. “Not only is it technically challenging, the forces and torque requirements involved are also very high.”

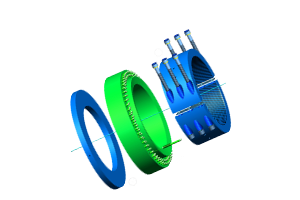

One of the biggest challenges they encountered when developing the Superbolt Tool was optimizing the ‘scroll drive technology’ — now known as UniForce — which needed efficient torque delivery to drive the Superbolt jackbolts. The technology was derived from a worm drive, which incorporates standard balls and a scroll. Rather than having one point of contact, the inventors decided to distribute it over several teeth in order to increase efficiency.

“It took me many hours to calculate the helical path of the scroll because it’s forever changing its diameter as it constantly engages the balls in the ball gear when it rotates around,” says McPhee.

It took me many hours to calculate the helical path of the scroll because it’s forever changing its diameter as it constantly engages the balls in the ball gear when it rotates around.

McPhee and Armstrong also had to decide on the best way to align all the jackbolts and get them to the same starting position. Indeed, the jackbolts on Superbolt MJTs do not have a consistent starting point, which makes tightening them simultaneously complicated. If the jackbolts are not in the same starting position, once one has been tightened, they all stop moving.

This was solved with the use of a highly ingenious ratcheting drive cassette, which only needs a simple battery drill for operation. Now the main tightening can be performed using the Superbolt Tool with a power cassette attachment. “There’s still challenges out there,” explains McPhee. “But it’s all about servicing the customer and doing the best possible job for them.”

Putting customers first

Indeed, customers have been at the heart of the development process, something that is part of McPhee’s philosophy. “I studied industrial design and whilst there was heavy emphasis on engineering, it was also critical to think about the human side of things as well,” he explains. “That’s very important in terms of how I look at functionality.” McPhee wanted the Superbolt Tool to be quick, simple and easy to handle — and he succeeded.

“The Superbolt Tool is unique,” says Steve Greenwell. “Customers with many MJTs or those that have to undertake frequent maintenance will achieve impressive gains in efficiency and timing”.

The Superbolt Tool is unique. Customers with many MJTs or those that have to undertake frequent maintenance will achieve impressive gains in efficiency and timing.

Although the Superbolt Tool has just been released, McPhee’s mind is already racing with potential developments. “The sky’s the limit with the Superbolt Tool,” he says. “There’s a lot of scope out there for future development and I’m really excited. One of these days it could end up on a space station – who knows where we go with this.”

Name: Andy McPhee

Title: Research & Development Engineer at Nord-Lock Group

Age: 49

Education: Postgraduate degree in Applied Science – Industrial Design from Queensland University of Technology

Professional background: Automotive design, hovercraft manufacturing, irrigation, software design

Passion: Solving problems that enhance people’s lives

Inventions: Inflatable tent, carbon fiber bicycle, mobile solar powered lights, bicycle rear-view mirror

How does the Superbolt Tool work?

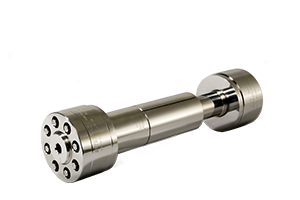

The key principle behind the Superbolt Tool is powered by UniForce Technology – invented by Nord-Lock Group. The patented technology consists of a unique scroll and ball drive mechanism for uniform and high transfer of torque. In operation, effective torque amplification is achieved in a very compact design – with input torque kept to a minimum. Tailored cassettes, which attach to the main drive unit, are used to transfer the necessary torque equally to each of the Superbolt tensioner jackbolts.