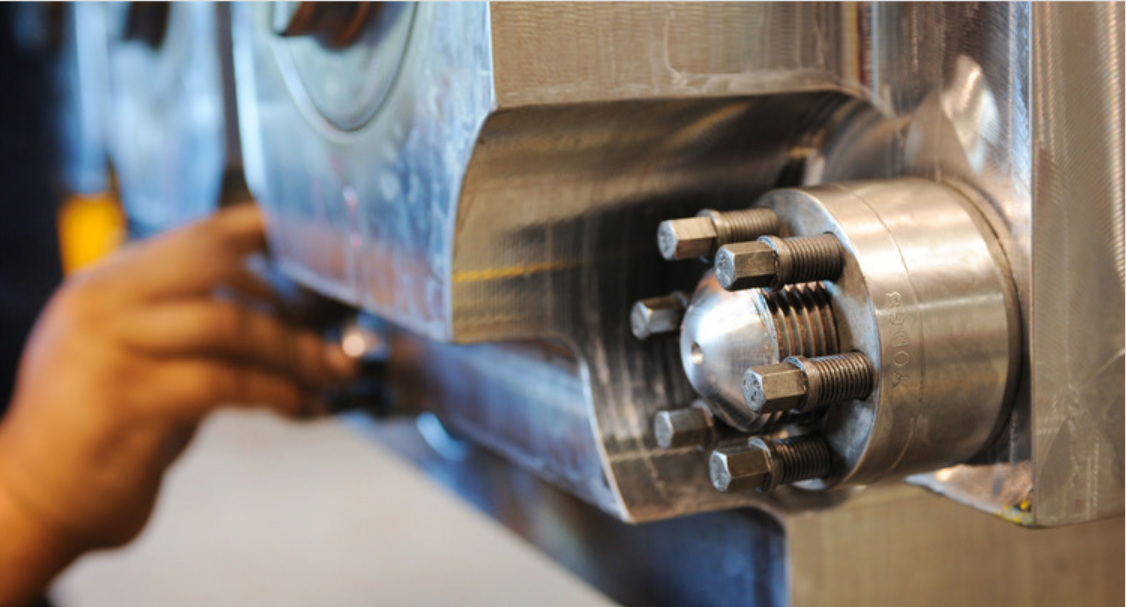

SUPERBOLT® CUSTOM SOLUTIONS

Our extensive experience spanning decades has positioned us as leaders in the field of tensioning. Together, we'll work closely with you to determine the most effective solution for your unique application. Trust in Superbolt for comprehensive support at every stage of your journey, including post-sales assistance.