Engineers need to plan for the safe transportation, handling, and assembly of these large and delicate components. Ensuring proper lifting, securing, and connection techniques during installation are crucial to avoid damage and ensure proper alignment and balance.

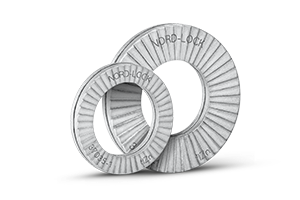

Nord-Lock Group products address challenges related to vibration, dynamic loads, corrosion, and maintenance requirements, contributing to the longevity and performance of the wind turbine system in offshore environments.