Wind turbine towers consist of numerous bolted connections, which are distributed throughout the structure. This large quantity of connections increases the complexity of maintenance and requires comprehensive inspection and maintenance plans to ensure all connections are properly addressed.

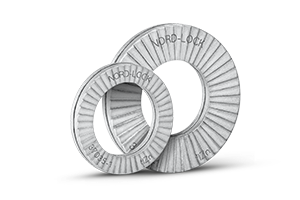

Wind turbine towers are often degraded due to harsh conditions making repairs difficult, expensive, and time consuming. Nord-Lock Group products can improve structural integrity and reduce maintenance time.