The installation and maintenance of wind turbine blades involve significant costs, including equipment, labor, and downtime for the turbine. Conducting repairs or replacing damaged blades can be time-consuming and result in decreased energy production until the turbine is fully operational again.

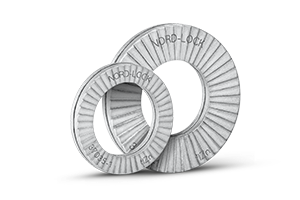

Nord-Lock Group solutions can assist in the installation and maintenance of rotor blades, leading to decreased maintenance time.